From Zeke Valtz

I finally have enough data to really stake my position about your company's electronic ignition system. Let me be clear, it's terrific and I'm thrilled with it. Here's the whole story.

For years I have wanted an improved ignition system for my airplane. The Lasar Ignition from Unison was the only option for certified aircraft but it was very expensive, orphaned by Unison, and the technology it used was not optimal. I watched with envy as technology moved forward in the homebuilt community - but those of us with certified aircraft were left behind. But in the spring of 2012 I read that ElectroAir Ignition Systems of Michigan had a system STCed for certified aircraft. But there was another problem - they were only approved for single engine aircraft - not the twin I wanted to install it on. I was hoping it was only a matter of time.

I spoke with Mike of ElectroAir and he said they had a twin lined up for certification and were planning to get twins added to the STC shortly. Murphy had something to say about this. That fall Mike and I decided to use my Twin Comanche as the certification test bed. I delivered the plane to Port Huron, MI for the installation. Two weeks later I came back and did the engineering and certification test flights. Everything went perfectly and I flew home with an approved Electronic Ignition System installed. I was thrilled. But everyone wants to know - does it make a difference?

An EIS produces benefits as a result of three items: altering the timing and duration of the spark and producing a hotter spark. The timing benefits become more substantial with higher altitude and lower power settings because the timing gets advanced more and more as your power setting is reduced. The longer duration and hotter spark are in effect at all times.

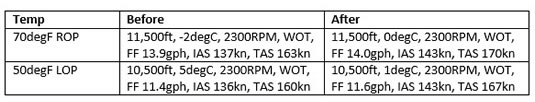

I am a data junkie and my plane is well equipped with engine instrumentation: JPI EGT, CHT, digital fuel flow, and an Aspen PFD that displays true airspeed. Furthermore, I fly the plane very consistently. I always set power exactly per the POH and adjust for non-standard temperature and pressure. For years I knew that if I set 65% precisely, I would get 146 KIAS. At 9,000 feet that produced 167 knots true airspeed. This was replicated on countless flights and was a predictable as a clock.

With the ElectroAir, my 65% power cruise speed has increased from 167 KTAS to 171 KTAS. At the same time, my fuel burn has decreased from 15.2 GPH to 14.2 GPH. At my old speed of 167 KTAS, my fuel flow is 13.2 GPH - a reduction of 2 GPH (13.1%) in fuel flow. That's a savings of $12.88 per hour. Furthermore, it is exactly in line with my expectations when installing the system. I prefer to take some of the efficiency gains, give some of that fuel back to the engine, and produce more power and go faster. But the full savings is there if I want it.

I have yet to try 55% power at 11,000 MSL but the savings should be even better at that altitude and power setting.

Since installation I have operated the aircraft 132 hours with virtually no hiccups. If money talks, I have started converting the 12 aircraft in my flight school to the ElectroAir EIS.

Zeke Valtz - Horizon Aviation, Inc.

Bill has said that he didn't buy the Bonanza to go slow. Needless to say, Bill is quite happy with his aircraft's performance after the Electroair system was installed. Bill's aircraft is seen here in for some routine maintenance at one of Electroair's Installation Centers - Carson Aviation Services in Carson City, NV. Thank you Bill for the information and feedback.

Bill H.

Bill has said that he didn't buy the Bonanza to go slow. Needless to say, Bill is quite happy with his aircraft's performance after the Electroair system was installed. Bill's aircraft is seen here in for some routine maintenance at one of Electroair's Installation Centers - Carson Aviation Services in Carson City, NV. Thank you Bill for the information and feedback.

Bill H.